When it comes to point-of-sale displays, structure and branding often get all the attention — but product fit is what quietly determines whether your display succeeds or fails.

A well-designed display isn't just about holding product — it's about holding it securely, efficiently, and attractively. Misjudging the number of units per shelf, stacking orientation, or weight balance can lead to poor shopper experience — or worse, structural failure on the retail floor.

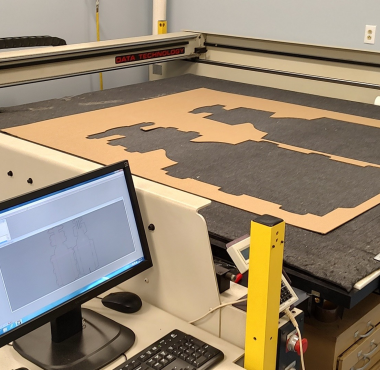

At Hawver, we engineer every display to your product's exact specifications — no guesswork, no shortcuts.

What to Think Through:

1. How Many Units Per Shelf or Tray?

Is your display meant to hold 8 boxes or 12? Rounding up to "fit more" without engineering for weight and balance can lead to bowing, tearing, or collapse. We prototype every design with real product to prevent that.

2. Is There a Plan for Refill Stock?

Are store associates expected to restock mid-campaign? If so, the design must accommodate refill access without compromising structure. If not, the load must last the full promotion window — and the board strength needs to reflect that.

3. Are Products Front-Facing or Stacked?

Front-facing product displays enhance branding and visibility — but require more real estate and support. Stacked items save space but need reinforced trays. We design around both to ensure stability and visual impact.

Engineered for Stability. Designed for Conversion.

For 44+ years, Hawver has helped brands get the most out of every square inch of display space — without compromising structure, style, or safety.

Need help sizing your next display the right way? Contact Derek@hawver.com for free die lines or to test-load your product in a real-world prototype.